Heat pump tumbler dryers use a similar technology to the systems used for heating and cooling homes. They are most easily recognisable by their lack of a visible vent.

The heat pump tumble dryer drying circulates hot air, which absorbs the moisture from wet clothes. This moisture then continues through a processing system that evaporates it, leaving the clothes dry.

The process of evaporation raises the issue of condensation caused by the heat pump tumbler dryer. The heated air will travel through a drum until it gets to the evaporator. This is the area where the moisture is removed from the main system.

There is a holding system that stores the condensed moisture. This could be a tank or a tray, which must be emptied.

Overall, this design is more efficient than previous systems and uses a significantly lower temperature to dry the clothes.

Heat Pump Tumble Dryers and Condensation

Heat pump tumble dryers produce hot air that circulates through the system. In the process, this heated air will eventually hit areas that are cold and made of metal.

This can include the walls and windows of the dryer, for example. The difference in temperature between the hot air and cold surface can increase the level of condensation. This is why not all tumble dryers will display the same amount of collected moisture.

Moisture will collect on these surfaces, and this process is called condensation. When the tumbler drying is located in a room with a proper temperature setting, there will be less condensation. The difference between the temperature of the cold surfaces and the hot air increases the amount of condensation.

The Heat Pump Dryer’s Design

Heat pump dryers are designed to prevent problems related to condensation such as mould and mildew. The dryer can do this by routing the collected water into the contained area.

This type of dryer can also be located anywhere in the home because there is no need for a vent to route the air to the outside.

However, there are some circumstances in which condensation might still occur.

Areas where there are high levels of humidity can affect the dryer differently. If the humidity in the environment is very high, you might notice an increase in the level of water appearing on the outside condensing coils.

Nearby surfaces can also collect some of this moisture. This small amount of moisture should still be wiped from the coils every week to prevent mould and mildew from appearing in the area.

Heat Pump Tumbler Dryer Efficiency

Although the heat pump tumbler dryer functions in a similar way to a traditional condenser, there are certainly benefits for using this technology.

Previous generations of tumble dryers would simply route the hot, moist air through a vent system to the outside. This wastes all of the energy used to heat the air in the first place, and that drives up the cost of drying clothes.

Heat pump tumble dryers approach the same problem from a different angle. This design enables the system to cool the warm air instead of heating new air continuously.

These dryers significantly reduce the amount of heat used overall because the air is heated less than in traditional dryers. This energy efficiency is reflected in the lower cost of running a heat pump dryer.

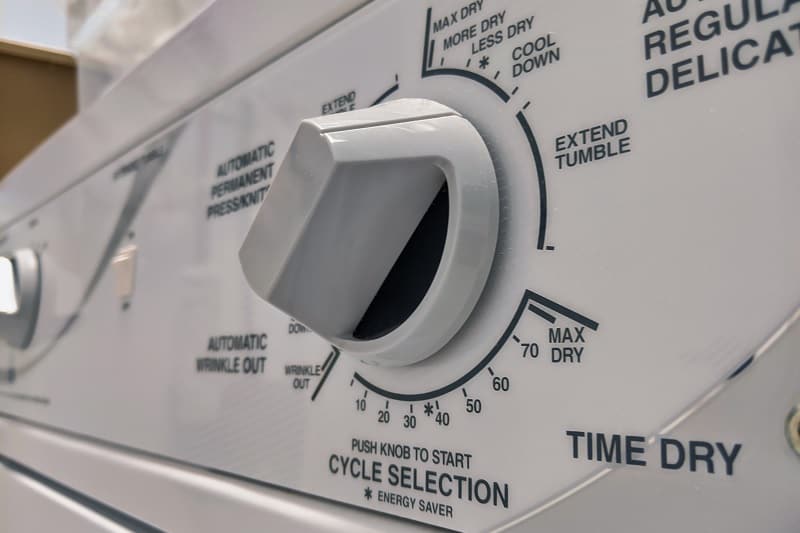

Moisture Sensors in Heat Pump Dryers

The moisture in the clothes is monitored by a sensor. This piece of technology will cause the unit to shut off once it determines that the clothes inside of the dryer have fully dried.

Malfunctioning sensors could contribute to excess condensation in some cases.

After each load of laundry, you will need to remove and empty the lint tray and the water collection tray where the condensed moisture is stored.

Some dryers can also be modified to increase ventilation, which reduces the condensation.

In The Wash is your guide to the best laundry and cleaning products, tips and tricks. Our mission is to solve the UK’s cleaning and laundry dilemmas!